Introduction

PVD stands for Physical Vapour Deposition, a process where metal surfaces like hinges, door pulls, and lever handles undergo coating inside a vacuum chamber with hard-wearing metals such as Zirconium.

Euroart’s PVD coating on door hardware offers superior resistance to corrosion and scratches compared to electroplated products. Our PVD-coated items typically exhibit high temperature durability for outdoor conditions, excellent impact strength, abrasion resistance, and increased durability, reducing the need for additional protective coatings.

The finish is both highly durable and elegant.

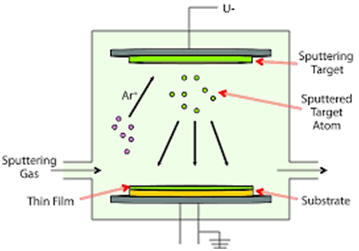

The PVD coating process involves the following stages

- We hang individual products, which are either brass or stainless steel base, on strings and clean them with chemicals to prepare the surface for coating.

- After drying, we place the parts in a PVD chamber and use reactive gases such as nitrogen and acetylene with certain metals to form a thin metal alloy that coats the products.

- We remove the products from the chamber after they cool down and conduct a QA/QC process to verify uniform coating and prevent air bubble formation.

EuroArt’s PVD finish consists of two coatings. The base coating is a 6?m (0.006 mm) thick PVD-black layer, which matches the hardness of many natural base metals. Following the PVD deposition, we apply a second coating of transparent colored lacquer (baking lacquer) with a thickness of 20~30?m (0.02~0.03mm). This PVD coating technique results in a surface hardness of 3000HV, significantly higher than the 800HV typically achieved with traditional plating (measured using the Vickers Hardness Test).

The Euroart process pictorially is demonstrated below :

1.The stages

2. PVD Process

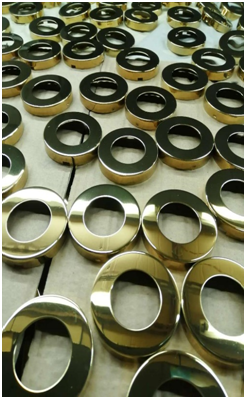

Images of the PVD process as done in the factory can be found at the end of blog.

Maintenance of PVD Black finish

PVD treated door furniture is recommended for areas subject to harsh climatic conditions. The PVD treated door hardware products are resistant to salt spray which makes them more ideal for use in external applications compared to lacquered or painted metal that tend to tarnish fairly quickly.

The PVD coating makes stainless steel base material more resistant to scratches, but it does not make it completely scratch-proof. PVD-coated products require virtually no maintenance and guarantee no discoloration.

You can perform periodic cleaning of products with a soft cloth dampened with water, avoiding aggressive detergents. Regular cleaning enhances the longevity of its appearance and quality, similar to any metal finish. However, like any surface, deliberate attempts to scratch or damage it will result in scratches.

At EuroArt, we provide a comprehensive line of door hardware, including an exclusive range of mortise locks, lever handles, cylinders, hinges and accessories. Our manufacturing and production process guarantees a strict quality management system and compliance to highest standards.

Appendix A

Images of the PVD process from our Manufacturing Center